LASER CLEAN GLOS

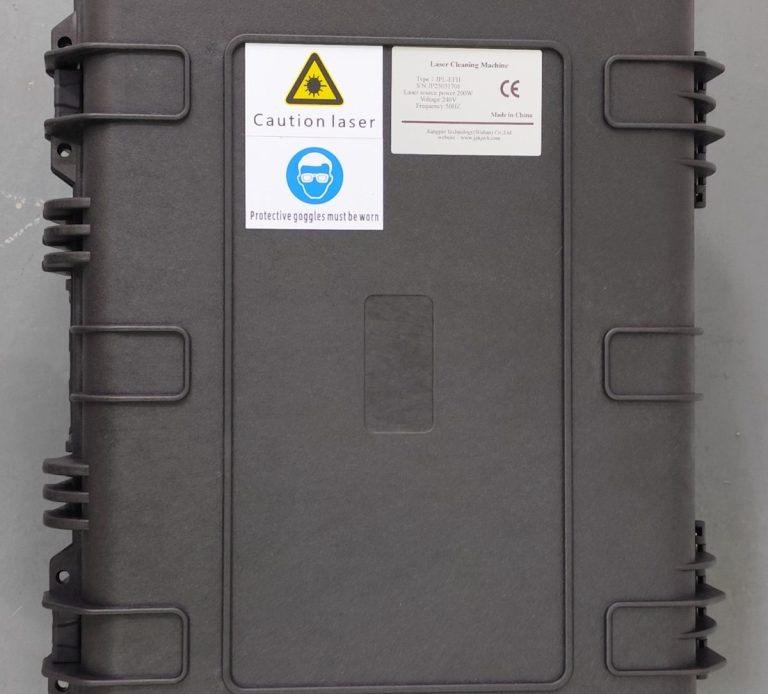

NEW MACHINE UP & RUNNING!

All Testing now done. Please contact us for more details.

- State of the art 200W PORTABLE LASER CLEANING MACHINE which will allow us to carry out more ON-SITE work in a clean & enviromentally friendly atmosphere to clean the likes of WOOD-STONE-BRICKWORK-METALWORK etc including GRAFFITI REMOVAL

Laser Cleaning Specialist for Gloucestershire & Surrounding Areas.

Transforming Surfaces, Restoring Glory

At Laser Clean Glos and in association with PEAKY SANDBLASTING LTD, we can can also offer the following services which specializes in a wide array of cleaning services including: 'CHEMICAL STRIPPING' - 'FIRE & SMOKE DAMAGE CLEANING' - 'GRAFFITI REMOVAL' - 'SAND BLASTING' - 'STONE BLASTING' - ' SPRAY FOAM INSTALLATION & REMOVAL' and 'WOODWORK TREATMENT', transforming everything from metalworks to household surfaces with unparalleled precision and care. All the above we can deliver exceptional results that breathe new life into your space. Experience our on-site or in-house cleaning service today!

*You can liaise with us at the bottom of this page or Contact Us with any questions or help you may require*

What can be cleaned using a Laser:

METALS: Aluminium-Cast Iron-Steel & Many More Surfaces including

FIBRE GLASS-CERAMICS-WOOD-PLASTICS-COMPOSITES-

STONE-CHROME & SOME TYPES of GLASS. More to be added as we go forward.

What is Laser Cleaning?

Fibre laser cleaning machine is widely used for cleaning the surface of materials, it can remove the object surface resin, the paint, the oil pollution, stains, dirt, rust, coatings, etc.

Laser rust removal is one of the main applications of laser cleaning machines, so it is also called a laser rust remover machine. Laser rust removal can clean rust from any equipment.

Fibre laser cleaning machine has a good cleaning effect on iron, carbon steel plate, stainless steel plate, mild steel gear, aluminium plate, paint layer and other materials.

Industrial laser cleaning machine can be used to clean oxide layer, surface paint removal treatment; clean surface oil, stains, and dirt; clean rubber mould residue.

Meet the requirements for equipment cleaning in the shipbuilding industry, auto parts, rubber moulds, machine tools, environmental protection industries and other fields.

Remove metal oxides or lubricants before welding for better welding results; clean the seam after welding to make it more aesthetically pleasing.

High power laser cleaners are ideal for industrial cleaning. It has a faster cleaning speed and allows a larger area of cleaning, and has a good effect on rust removal on the surface of mechanical equipment, paint stripping on re-treading products, and tire mould cleaning.

1. Precise cleaning. Laser machine cleaning can easily reach the corners of complex design objects for precise and localized cleaning.

2. No damage to the substrate. Fibre laser cleaning adopts non-contact cleaning method, no abrasive, no mechanical force, and no damage to the surface of the object.

3. Safe and pollution-free. The laser cleaning metal process does not use chemicals and other media, does not produce chemical pollution and is more environmentally friendly.

4. Easy to use. Laser cleaning machine has low technical requirements for operators and low labour intensity. The average worker is trained to handle multiple metal rust removal projects on his own.

5. Low running cost. Fibre laser cleaner rust removal is many times faster than other traditional cleaning methods, reducing labour costs. Moreover, the laser rust removal tool can be used when it is powered on, no consumables, and no special maintenance.

Laser technology has been widely used in the industrial field, and one of the amazing creations of laser is a laser cleaning technology. By selecting the specific material to be removed, laser cleaning machine offer a quick and set-and-forget solution for many industries. Fiber laser cleaning machine is widely used for cleaning the surface of metal materials such as rust removal, paint removal, and decontamination. It can achieve selective cleaning, accurate positioning and high cleaning efficiency.

What is Laser Cleaning?

Laser cleaning is a process that involves using a laser beam to remove rust, paint, oxides and other contaminants from metal surfaces. It is more efficient and effective than other traditional methods such as chemical agents and mechanical scraping. No chemical cleaning fluid, no consumables, safe and environmentally friendly.

What is a Laser Cleaning Machine?

The laser, cleaning machine is a handheld laser cleaning equipment composed of a fibre laser generator, a laser cleaning gun, and a laser cleaning system. It uses pulsed laser or continuous wave laser to irradiate the metal surface, and the pollution layer can instantly absorb the energy of the focused laser, so that the rust, paint or oil on the surface can be peeled off or evaporated instantly, and the coating attached to the metal surface can be removed effectively at high speed. Because laser cleaning uses a non-contact method to remove contaminants from the surface of the material, there is little damage to the metal substrate.

What you should know before using a laser cleaning machine?

Before we can provide advice to you with the right laser cleaner, we need to know what type of product we are cleaning and what are the main contaminants on such products. According to this issue, we need to communicate with you the following points:

General size, area and geometry of the work piece to be cleaned.

Material base.Type and thickness of contamination.Required cleaning rate.

Requirements related to laser process operation.

Once we better understand your application, we will test our laser cleaning machines for the best laser configuration for your needs. We can provide you with laser cleaning videos so that you can intuitively understand the effect of laser cleaning.

Laser cleaner can solve the problems that traditional rust removal methods cannot solve. Even for special-shaped metal parts, the laser, cleaning machine can perform rust removal operations through precise positioning of the laser beam. That is to say, as long as the place where the laser can be irradiated, the rust, oil stain, paint layer or oxide layer on the surface can be effectively removed. The laser cleaning gun adopts a hand-held design, which is easy to use and can flexibly deal with various objects and angles.

The application of laser cleaning machines provides a cost-effective solution for industrial cleaning, which can reduce cleaning time and maintenance costs. Every component of a laser cleaner delivers consistent, reliable performance with little or no maintenance.

Either use the below form for any help and advice you may need or go to 'CONTACT PAGE'

If you have Photos or Videos then please email them to:

enq@lasercleanglos.co.uk